Flo-Get

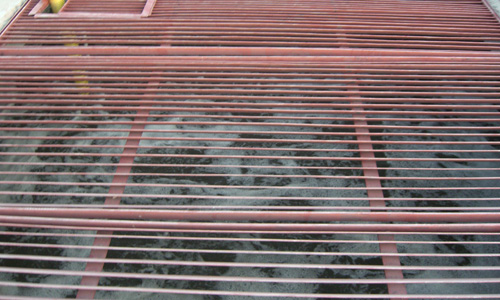

Flo-Get is an original WATER DYNAMICS system which can be used for the simultaneous aeration mixing of all types of liquids. Thousands of installations in municipal and industrial wastewater treatment, liquid manure, fish farming and all types of equalization tanks prove the reliability efficiency and versatility of the system.

The Flo-Get system is based on coupling one or more WATER DYNAMICS submersible air blowers to one or more WATER DYNAMICS ejectors. Submersible air blowers of different power and hydraulic performances can be connected to ejectors of different flow capacity to meet a wide range of system requirements.

The Flo-Get system, air blower + ejector,

is designed for installations with a highly variable load. The combined aeration and mixing action ensures a high efficiency operation throughout the entire tank without any dead spots. When used in combination with mixers, Flo-Get aerators provide even higher oxygen transfer efficiency and ensure complete mixing without settling or triggering off any anaerobic activity even when the Flo-Get units are stopped.

Advantages

- Quiet operation

Flo-Get aerators operate completely submerged. This results in very low noise levels, compared to non submerged equipment.

- No aerosol effect

No sprays or dispersion of liquid particles into the atmosphere are generated with Flo-Get aerators. This minimizes contamination of the surrounding air and ensures better working conditions for plant personnel and neighbors.

- Versatility in use and ease of installation

The Flo-Get system is extremely flexible and versatile. It can be adapted to any type of tank regardless of its shape, size or depth.

Installation is easy and requires no special work to existing structures.

The large nozzle sizes provide good solids through let capabilities, minimizing the risk of clogging the ejector.

Flo-Get

Maintenance is limited to periodic inspection of the submersible air blower, once or twice a year.

With different ejectors on the same air blower the FLO-GET system can perform different tasks, such as:

- Oxygenation - CO2, neutralization - Sludge treatment

- Mixing - Foam suppression, and Homogenization, (mixing).

Combining Flo-Get aerators with submersible mixers can provide biological treatment as a Sequence Batch Reactor (SBR) where the biological treatment is altered between aerobic and anoxic processes for removal of nutrients.

If the suction pipe is connected to an adjacent tank, it is possible to pump with level differences of up to 5 meters, see figure A, page 5.

If the ejector is removed and replaced by a pipe attachment, the system becomes a submersible pump which can be used to empty tanks and sumps, or transfer liquids, see figure B, page 5.

- A wide range of aeration products

WATER DYNAMICS has the different types of aerators, knowledge, and engineering capacity to advise the best solution for any application.

Ejector principle

a water dynamics submersible air blower generates the primary flow (water). the reduced cross section area in the nozzle accelerates the flow as it enters into the suction zone. a sufficient flow velocity lowers the pressure in this zone enough to suck in air (secondary flow). when passing the mixing zone the primary and secondary flows mix completely due to turbulence, and leave the diffuser as a water jet with fine air bubbles.